Upcoming Events

Join us for our Sponsored Webinar with Food Safety Magazine!

An environmental monitoring program (EMP) is an essential part of your food safety and HACCP plans. It helps ensure that your facility environment has been properly cleaned and sanitized and is fit for the production of safe food. In this webinar, industry veterans and independent experts will guide attendees on maintaining proper environmental conditions inside your plant, the selection of zones for sampling, and sampling techniques and oversight. They will also discuss pitfalls to avoid in your EMP, including program failures and common mistakes, and why these programs can fail to eliminate resident pathogen strains (e.g., Listeria, Salmonella) in facilities, with the meat/poultry and fresh produce sectors as examples. Other concerns to be addressed include relationships with testing labs and the need for comprehensive Listeria management.

From this webinar, attendees will learn:

- Environmental sanitation pitfalls to avoid, and how to ensure biological safety inside your plant

- Best practices and guidance for sampling

- Significant problems seen in EMPs, and why these failures occur

- The need for comprehensive Listeria management

Register Now

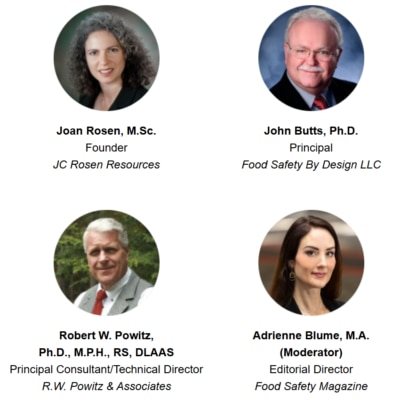

Speakers:

Join Us at IFT 2025 in Chicago!

📅 Dates: July 13-16, 2025

📍 Location: McCormick Place, Chicago, IL

🏢 Booth: S3002

We are excited to announce that the Nestlé Quality Assurance Center (NQAC) Dublin will be showcasing our services at the Institute of Food Technologists (IFT) Annual Event & Expo in Chicago!

Discover our comprehensive range of over 200 analytical methods designed to ensure the highest standards of food safety and quality. Don’t miss this opportunity to learn more about how NQAC Dublin can support your food safety and quality assurance needs. We look forward to seeing you there!

Join Us at IAFP 2025 in Cleveland!

📅 Dates: July 27-30, 2025

📍 Location: Huntington Convention Center, Cleveland, OH

🏢 Booth: Nestlé Quality Assurance Center Dublin

We are thrilled to announce that the Nestlé Quality Assurance Center (NQAC) Dublin will be exhibiting at the International Association for Food Protection (IAFP) Annual Meeting in Cleveland!

Discover our comprehensive range of over 200 analytical methods designed to ensure the highest standards of food safety and quality. Don’t miss this opportunity to learn more about how NQAC Dublin can support your food safety and quality assurance needs. We look forward to seeing you there!